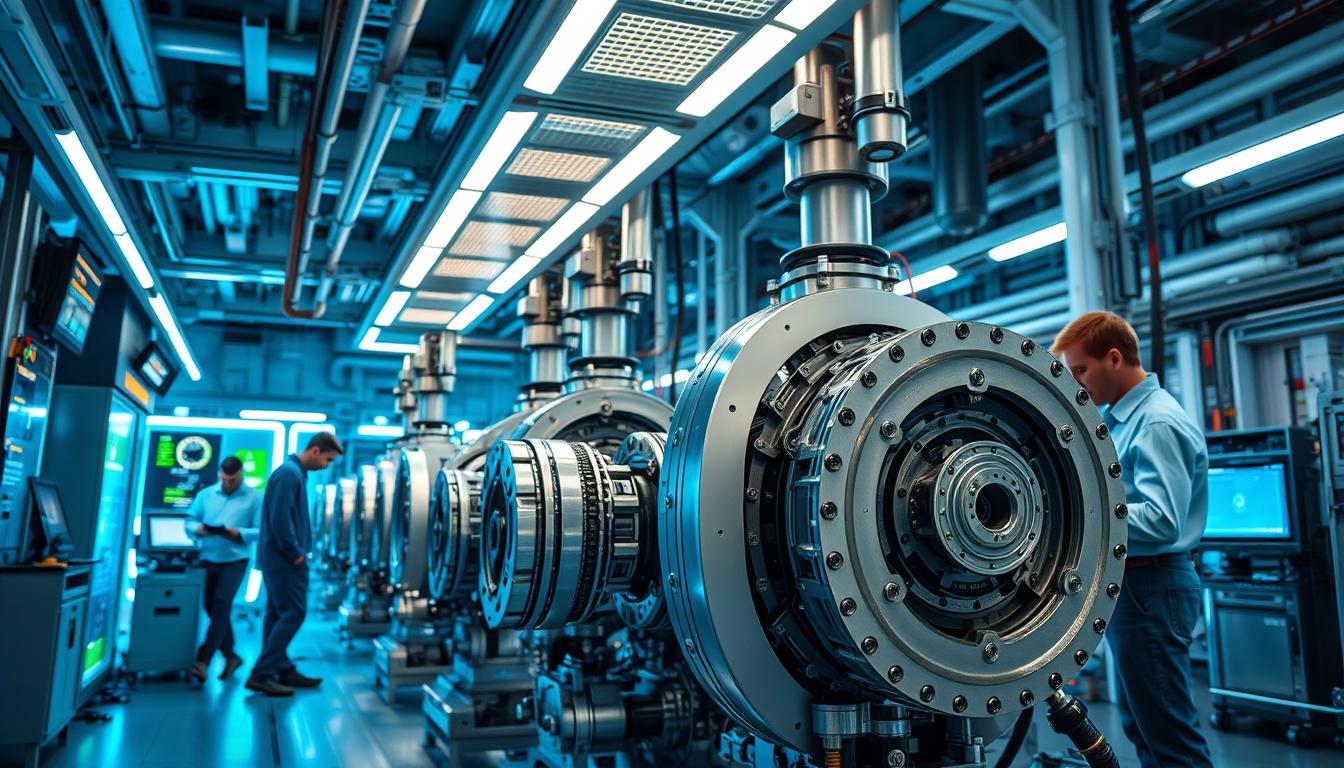

In our fast-changing world of engineering, low-ratio drives are getting a lot of attention. They transfer power well at lower speeds, making machines work better. With more torque and power, they help high-load machines work smoothly in many industries.

Experts in the field talk about how these drives save energy and make things more reliable. The American Society of Mechanical Engineers (ASME) says they also cut down on fuel use. This is because they make power use in heavy machines more efficient. Now, thanks to new tech, these drives are smaller and lighter. This makes them great for big and small machines alike.

Enhancing Efficiency in Engineering Applications

Low-ratio drive technology is key to better efficiency in engineering. It helps save energy and reduces machinery damage. This gives major benefits to how things work overall.

Energy Savings Through Low-Ratio Drives

Low-ratio drives let machines work at slower speeds but with high torque. This means they use less energy and cost less to run. The U.S. Department of Energy found that using low-ratio drives can cut energy use by 10% to 30%.

Reducing Wear and Tear on Machinery

Low-ratio drives also make machines more reliable by keeping speeds ideal. This reduces stress and damage to the parts. The International Society of Automation says this leads to machines lasting longer and needing less upkeep. That saves money over time.

The Advantages of Low-Ratio Drives in Modern Engineering

Low-ratio drives boost precision and control in engineering. Engineers can fine-tune adjustments and lift performance in machines. These drives excel in areas needing high accuracy, like robotics and automation.

Precision and Control in Performance

Low-ratio drives improve speed and torque control in precision engineering. Machines can work with high accuracy, making fewer mistakes. A study by MIT’s Department of Mechanical Engineering shows robots with these drives hit over 95% accuracy in tasks.

Applications in Robotics and Automation

Robotics and automation use low-ratio drives to increase efficiency. Companies like Siemens and ABB use them to make assembly lines faster and high-quality. These drives are key in pushing forward innovation in many fields.