High-Precision Actuators are becoming key in advancing automation technology. They improve control and efficiency in various fields. By using cutting-edge technologies, these actuators make precise movements possible. This precision is crucial in manufacturing, robotics, and healthcare.

As industries grow, high-precision actuators become essential for staying ahead. They are important in today’s quick market. The rising need for automation shows how vital these devices are. It also points to ongoing innovation in robotics and more.

Understanding High-Precision Actuators in Automated Systems

High-precision actuators are crucial in automated systems. They offer top-notch accuracy for many uses. These devices ensure motion is controlled precisely. This is key where small mistakes can affect performance. They work in various fields, like manufacturing and robotics.

What are High-Precision Actuators?

High-precision actuators convert signals into precise movements. They’re used in automated systems for tasks that demand high accuracy. You can find electric, pneumatic, and hydraulic actuators. Each type fits different needs, making them vital for modern precision technologies.

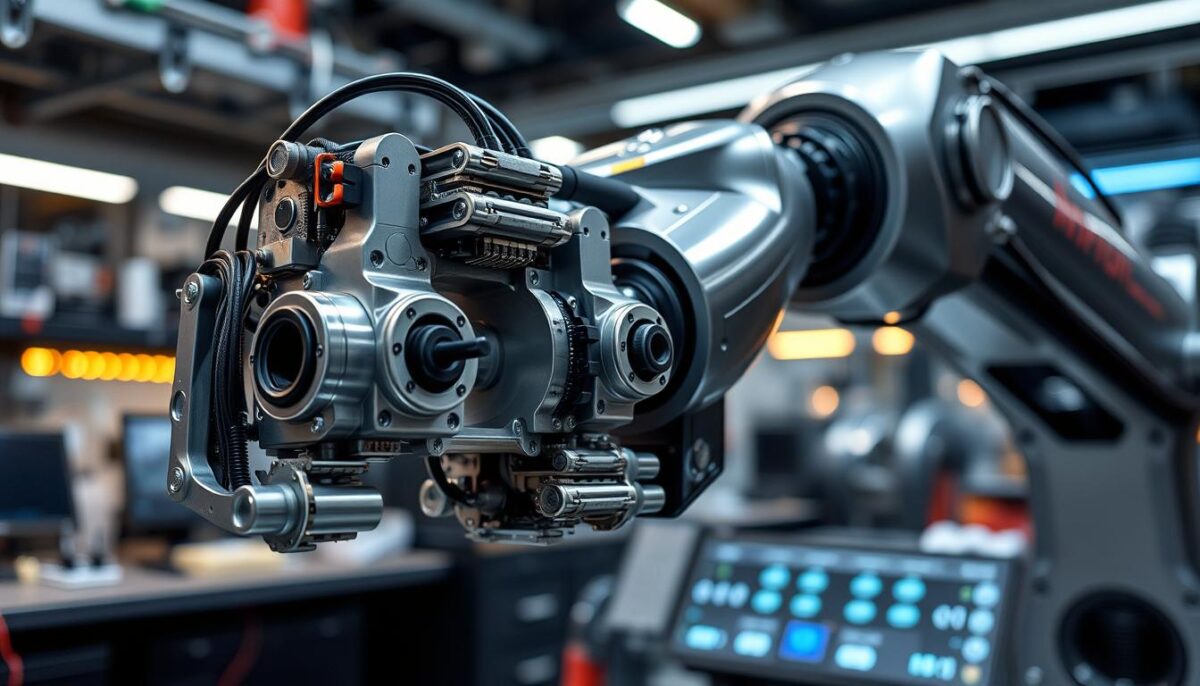

Key Components and Technologies

The success of high-precision actuators depends on their parts. Important components are:

- Motors that provide the driving force

- Sensors that monitor and relay position feedback

- Control algorithms which dictate motion sequences

- Feedback systems ensuring real-time adjustments

Advanced tech like servos and stepper motors boost these actuators’ precision. Closed-loop control systems refine their performance. They allow adjustments on-the-fly in automated setups.

| Actuator Type | Advantages | Common Applications |

|---|---|---|

| Electric | High efficiency, quiet operation | Robotics, CNC machines |

| Pneumatic | Rapid movement, lightweight | Packaging, assembly lines |

| Hydraulic | Powerful force, suitable for heavy loads | Construction, industrial machinery |

High-Precision Actuators: The Next Step in Automation

High-precision actuators are now key in industrial automation. They are known for their great dependability and flexibility. These tools are crucial for jobs needing exactitude and strict control, becoming indispensable in current manufacturing.

Applications in Industrial Automation

Actuators have a big part in boosting how things work in many areas. They are used in:

- Robotics, where they allow for accurate moves and placement.

- Assembly lines needing steady and precise actions.

- Packaging machines to keep a tight grip on speed and quality.

- Inspection systems, where being exact is key for ensuring quality.

The Robotics Industries Association (RIA) says using high-precision actuators in robots has really improved accuracy in making things. These devices make work smoother and cut down mistakes, proving their worth in the field.

Benefits Over Traditional Actuators

High-precision actuators come with benefits that set them apart from the old ones. The top pros include:

- Better repeatability, for the same results in tasks every time.

- Lower maintenance costs, helping businesses save money.

- They’re easier to add into high-tech control systems, making operations smoother.

A report in the Journal of Manufacturing Science showed these actuators can reduce task times by as much as 20%. Automation World also pointed out they save a lot of money in operation costs. This is because they use less energy and need less upkeep for better results.

The Role of High-Precision Actuators in Robotics

High-precision actuators greatly improve how robots work, allowing them to do complex tasks. They offer precise and quick control. This lets robots be more efficient in many industries.

Enhancing Performance and Efficiency

Using high-precision actuators changes how robots work with things around them. They let robots move with accuracy up to 0.01 mm. This accuracy is key for jobs on assembly lines and in surgeries, where small mistakes can be big problems.

Types of Robotics Utilizing High-Precision Actuators

Many kinds of robots use high-precision actuators. Here are some examples:

- Industrial Robots: Essential for tasks requiring repetitive accuracy.

- Collaborative Robots (Cobots): Designed to enhance human-robot interaction safely.

- Surgical Robots: Provide high levels of precision during medical procedures.

- Autonomous Vehicles: Utilize actuators for precise steering and movement control.

| Type of Robot | Application | Efficiency Enhancement |

|---|---|---|

| Industrial Robots | Automating manufacturing tasks | Higher production rates with reduced errors |

| Collaborative Robots | Assisting human workers | Improved safety and teamwork |

| Surgical Robots | Minimally invasive procedures | Enhanced precision and reduced recovery times |

| Autonomous Vehicles | Self-driving technology | Increased accuracy in navigation and safety |

The information highlights how important high-precision actuators are in robotics. These components make robots work better, showing how efficiency can improve in various areas.

Future Trends in High-Precision Actuator Technology

The future of actuators is lighting up with rapid tech progress. Smart actuators are a big part of this. They use artificial intelligence (AI) to work better and adapt faster. This makes systems more effective and flexible for many uses.

Recent automation conferences shared exciting news. IoT tech will soon let actuator systems monitor things in real time and predict issues. This will help businesses prevent problems, reducing downtime and boosting efficiency. Also, using lighter materials in actuators will save more energy. This leads to greener industrial actions.

The field is also seeing huge steps forward with micro-electromechanical systems (MEMS). Experts from the IEEE Robotics and Automation Society believe MEMS will expand actuator uses. Fields like medicine, cars, and electronics will benefit. These updates suggest big changes ahead, with a focus on smart, efficient solutions.