Gear-heads are essential in mechanical engineering. They help move motion and torque in many areas. These include robotics and cars. Today, we will compare two key types: planetary gear-heads and orbitless gear-heads.

Each type has its own unique features. It’s important to know these differences. This knowledge helps improve gear-head performance and select the best option for your project. By the end of this, you will know which gear-head matches your needs.

Understanding Gear-Heads: Key Concepts and Mechanics

Gear-heads are crucial in machines, impacting their performance significantly. Knowing how gear-heads are designed is vital for those working with these systems. We’ll dive into the basics of gear-heads, highlighting their design’s role in efficiency and effectiveness.

The Basics of Gear Head Design

Gear-head design involves a few main parts, including the housing and the shafts. The gears themselves are also key. Each piece is carefully crafted to work at its best. A top-notch gear-head can precisely control speed and torque, proving essential in many types of equipment.

Importance of Gear Ratios in Performance

Grasping gear ratios is key to harnessing gear-head power. These ratios affect how force moves from the input to the output, changing speed and force. A high gear ratio means more force but less speed, crucial for lifting heavy loads. On the flip side, a low gear ratio boosts speed but not force. Picking the right gear ratio is crucial for the best gear-head performance in any project.

| Gear Ratio | Effect on Torque | Effect on Speed | Best Use Cases |

|---|---|---|---|

| High (greater than 1:10) | Increases torque | Reduces speed | Heavy lifting applications |

| Medium (1:5 to 1:10) | Balanced torque and speed | Moderate speed | General machinery |

| Low (1:1 to 1:5) | Decreases torque | Increases speed | Applications requiring high speed |

A Practical Comparison of Planetary and Orbitless Gear-Heads

This section looks at planetary and orbitless gear-heads. We’ll talk about their designs, efficiency, and where they work best. Knowing these differences helps pick the right gear-head for your project.

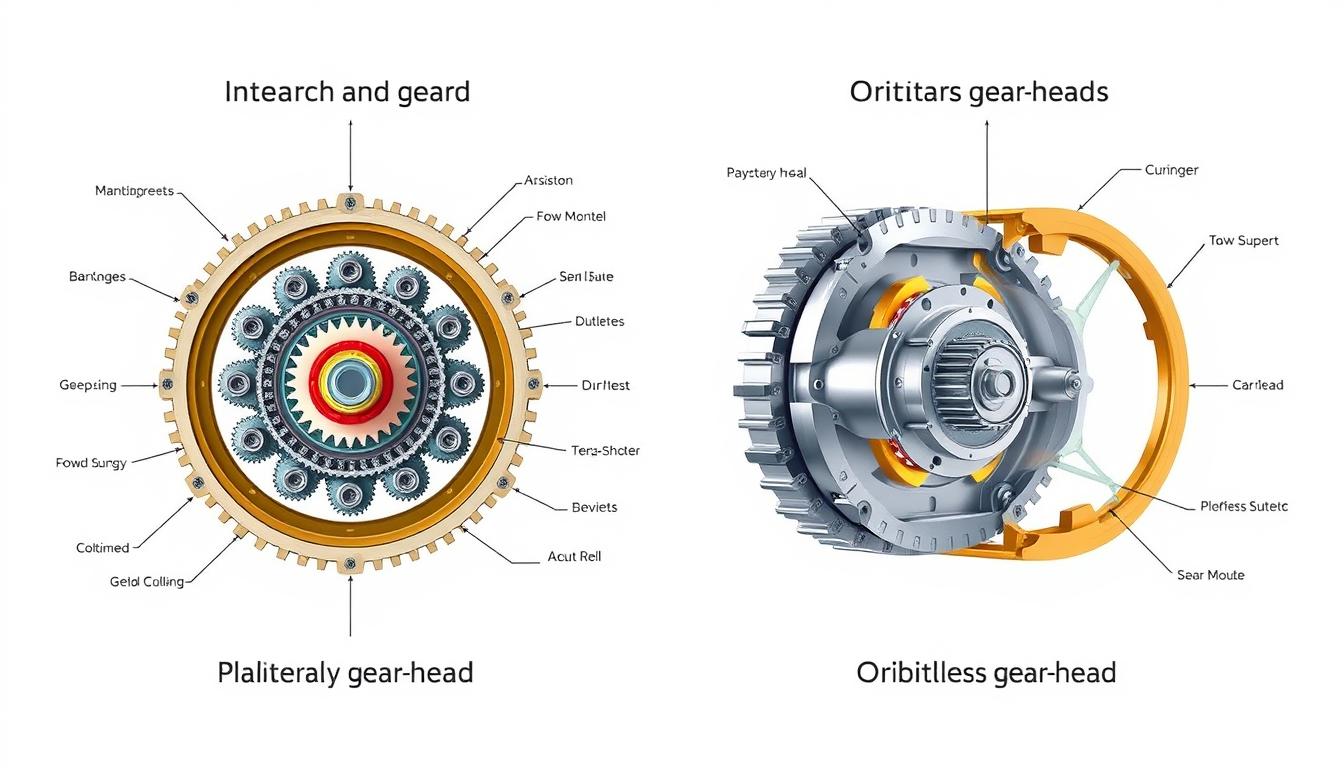

Structural Differences Between Planetary and Orbitless Gear-Heads

Planetary and orbitless gear-heads have key design differences. Planetary gear-heads have gears that move around a central gear. This setup is called a planetary configuration. Orbitless gear-heads use a different approach. They have a unique design that avoids traditional gears. This makes them more compact and reduces backlash.

Performance Metrics: Efficiency and Torque

Efficiency and torque are important when looking at these gear-heads. Planetary gear-heads are usually more efficient. They often reach efficiencies over 90%. But orbitless gear-heads’ efficiency can vary based on design and use.

Planetary gear-heads can deal with high loads. This makes them good for tough jobs. Orbitless gear-heads are lighter but might not handle as much torque.

Application Scenarios: Best Uses for Each Type

The choice between gear-heads depends on what you need for your project. Use planetary gear-heads for jobs that need high torque and small size. Examples are robotics and industrial machines. They are reliable with heavy loads.

Orbitless gear-heads are best where saving space is key. Think of handheld gadgets or small robots. They are perfect when size and weight matter most.

Choosing the Right Gear-Head for Your Project

Picking the right gear-head is crucial. Your project’s specific needs play a big role in this decision. You must consider the torque needs, space available, and how efficient it needs to be. These factors help engineers and hobbyists pick the perfect gear-head, ensuring everything works smoothly.

Space is a major factor to think about. If your project has tight space, orbitless gear-heads, which are smaller, could be best. But, if you need more power, planetary gear-heads are likely the right choice. It’s important to pick wisely to avoid extra costs and poor performance.

Choosing the ideal gear-head requires careful thinking. You need to weigh factors like how heavy it can be and how efficient it needs to be. This consideration is key whether you’re tackling a small hobby project or a big industrial task. Taking time to evaluate these aspects will lead you to success in your project.