In today’s fast-paced industrial world, the demand for better drive systems is growing. Orbitless drives offer a new way to cut down friction in machines. They do this by getting rid of parts like bearings that usually cause friction.

This means machines last longer because there’s less wear and tear. Companies like Schwartz’s Drive Technologies lead in making these drives. They help make machinery run smoother and save energy in many fields. We will explore how orbitless drives work and why they are so important for modern engineering.

The Basics of Orbitless Drives

Let’s dive into what orbitless drives are. They’re at the forefront of mechanical technology. Unlike traditional gears, they create rotation without as much friction.

What Are Orbitless Drives?

Orbitless drives are a big step forward in engineering. They don’t rely on the parts that most machines use to move. By using special shapes, they cut down on friction. This makes them run smoother and work better.

How They Function in Mechanical Systems

These drives work in a smart way. They mix unusual movements with special paths to be super efficient. When used in machines, they boost performance a lot. Research shows they’re a game-changer for many fields.

| Feature | Orbitless Drives | Traditional Drives |

|---|---|---|

| Movement Type | Direct Energy Transmission | Orbiting Motion |

| Friction Levels | Minimal | Higher |

| Mechanism Complexity | Advanced Geometric Designs | Standard Gear System |

| Operational Efficiency | High | Variable |

How Orbitless Drives Reduce Friction in Mechanical Systems

Orbitless drives are a big step forward in engineering. They bring better efficiency to mechanical systems through their design. These drives cut down on friction, which means they last longer and cost less to maintain.

They’re different from traditional drives in many ways. By understanding these differences, we can see why they perform better in various situations.

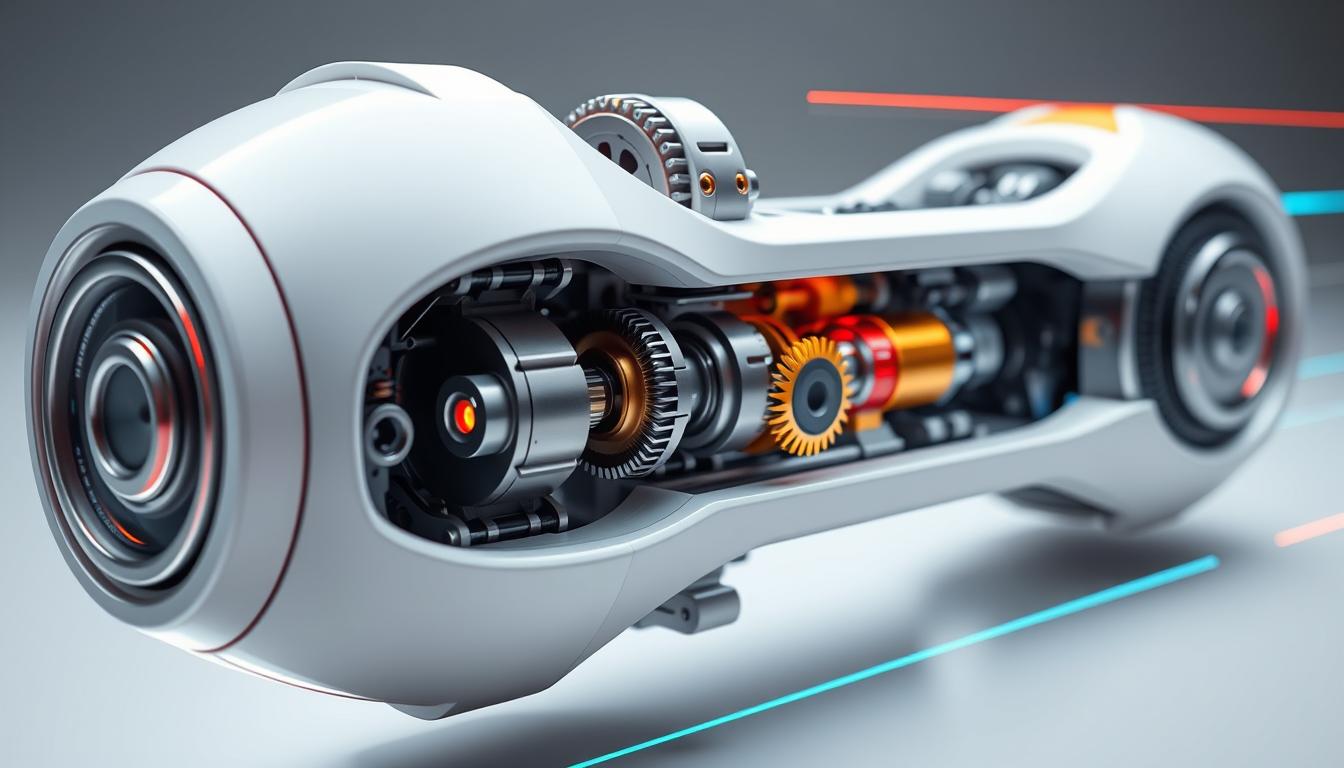

Innovative Design Features

The design of orbitless drives is truly advanced. They use special materials and designs that don’t touch each other. This reduces friction a lot.

The materials chosen have low friction levels. This drops the resistance during operation and makes the system more efficient. Because there are no contact points, the drives run smoother and last longer.

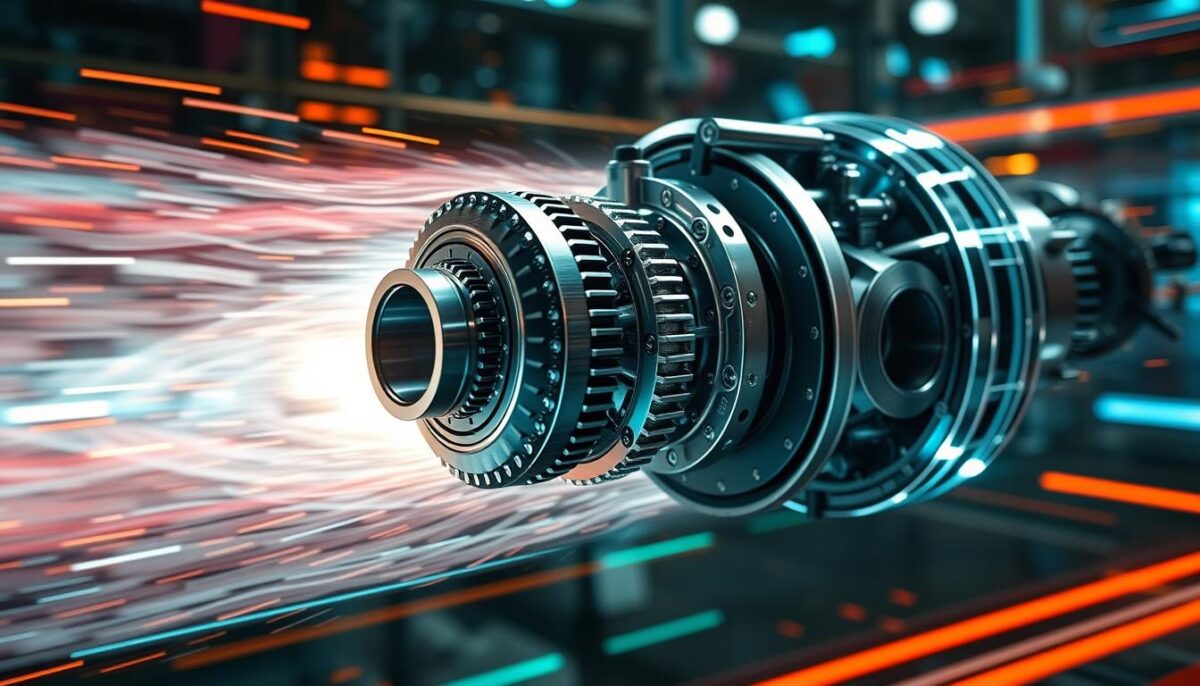

Comparison with Traditional Drive Systems

Orbitless drives and traditional systems are quite different. Traditional drives often have gears that rub together, causing friction and heat. But orbitless drives use energy more efficiently.

They save a lot of energy. Real examples from cars and planes show how these drives cut costs and boost effectiveness.

| Feature | Orbitless Drives | Traditional Drive Mechanisms |

|---|---|---|

| Friction Levels | Significantly reduced | Higher due to gear interactions |

| Energy Efficiency | High, with energy savings | Moderate, often leading to energy loss |

| Maintenance Requirements | Lower due to reduced wear | Higher, requiring regular servicing |

| Durability | Longer lifespan | Shorter lifespan due to wear |

Applications and Benefits of Using Orbitless Drives

Orbitless drives are revolutionizing various industries. They are used in automotive, aerospace, robotics, and consumer electronics. These systems are valued for their ability to meet unique demands.

In the automotive world, they lower friction. This leads to more energy-efficient and smoother vehicles. It shows how orbitless drives enhance performance.

Orbitless drives also stand out for making less noise. This is key in fields like consumer electronics and precision robotics. They have a longer lifespan and lower maintenance costs. This makes them appealing for streamlining operations.

These advantages push industries toward more sustainable practices. It matches the global shift towards saving energy.

Looking forward, the use of orbitless drives is expected to grow. This growth is spurred by technological advancements. They offer exciting possibilities for innovation across industries.

They could improve electric vehicle performance or make automated processes more efficient. Orbitless drives are changing mechanical design. They support a future that values efficiency and sustainability.