In mechanical design, knowing how Orbitless Drives differ from Planetary Drives is key. Each system has unique features and benefits important for design and application. This article helps compare the two, highlighting characteristics that set Orbitless Drives apart.

By understanding these differences, readers will make better decisions. This can improve their projects and boost performance.

Understanding the Basics of Orbitless Drives

Orbitless Drives are a big leap in drive technology. They have a special design that skips the usual orbits seen in traditional systems. This unique feature leads to better efficiency and functionality. It’s key to understand what Orbitless Drives are to see their wide impact.

What are Orbitless Drives?

Orbitless Drives are made to move smoothly without the typical rotational path of planetary drives. They use advanced mechanics. This allows for straight torque transfer, smoothing operations and cutting energy loss. They shine in places where precision and less resistance matter a lot.

Key Features and Benefits of Orbitless Drives

What makes Orbitless Drives special are their features:

- Less friction means less wear and a longer life.

- Their small design fits into tight spaces easily.

- They transfer torque well, boosting performance for tough tasks.

Choosing Orbitless Drives brings many advantages to different fields:

- They need less upkeep, saving money over time.

- They’re reliable for important jobs that need steady performance.

- These drives are versatile, suitable for robotics, automation, and aerospace.

| Feature | Description | Benefit |

|---|---|---|

| Reduced Friction | Minimized moving parts and contact points. | Longer lifespan and lower wear. |

| Compact Design | Small footprint compared to traditional systems. | Easy integration into various applications. |

| Enhanced Torque Transfer | Direct and efficient power transmission. | Improved performance in demanding tasks. |

| Lower Maintenance | Fewer parts needing regular upkeep. | Cost-effective and reliable over time. |

| Versatility | Applicable across numerous industries. | Flexible usage in diverse environments. |

Comparing Orbitless and Planetary Drives

Orbitless and Planetary Drives are different in design, performance, and how easy they are to use. Knowing these differences helps choose the right drive for your needs. We will look at what makes each drive unique.

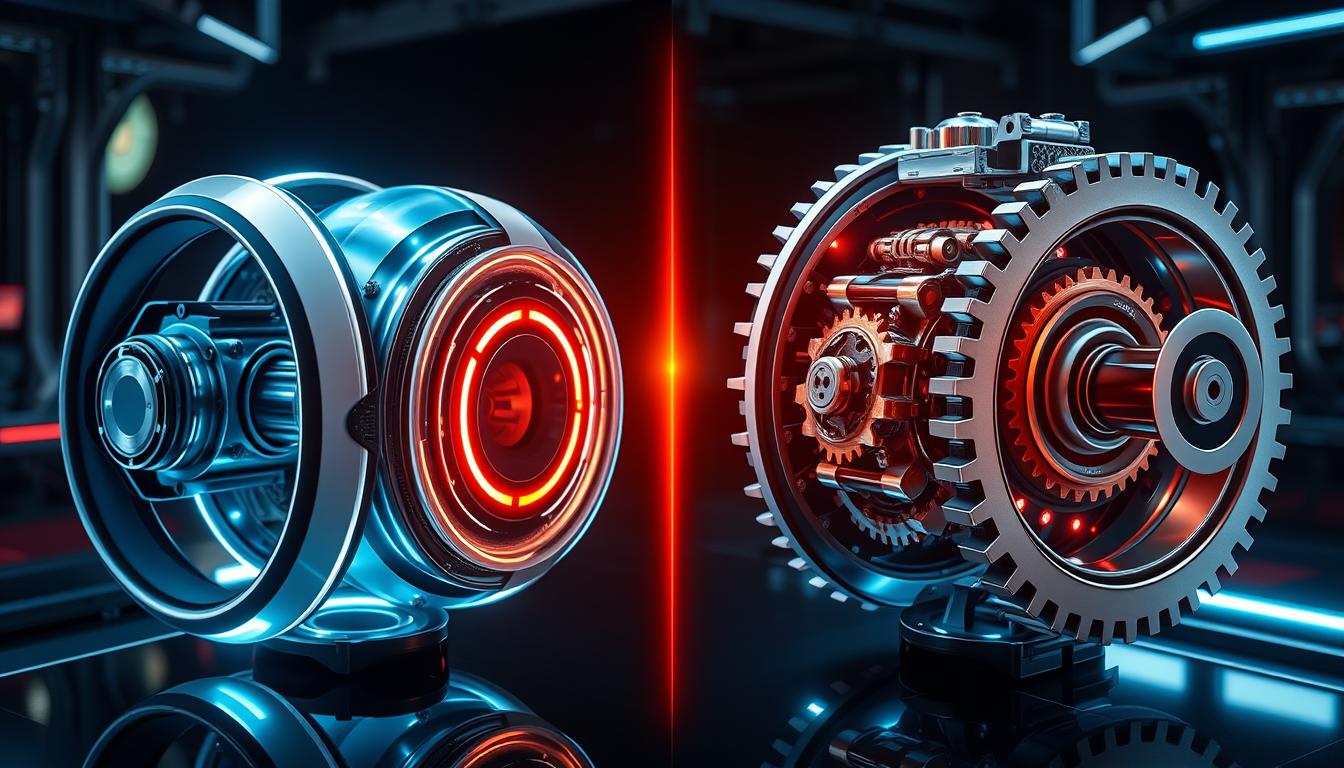

Design Differences Between Orbitless and Planetary Drives

Orbitless Drives don’t have orbiting parts. This makes them light and compact. But, Planetary Drives have gears moving around a central gear. This means they can be bigger and heavier, affecting where they can be used.

Performance Metrics: Which Drive Reigns Supreme?

When comparing the drives, looking at performance is key. Points to consider include:

- Efficiency: Orbitless Drives are usually more efficient, losing less energy.

- Load Capacity: Planetary Drives can handle bigger loads, good for tough jobs.

- Speed Ratios: Orbitless Drives offer smooth operation at high speeds.

Checking these points helps figure out the best drive for your needs.

Applications and Usability Considerations

Think about how easy it is to use each drive. Orbitless Drives need less space and are easier to care for, perfect for small spots. Planetary Drives last longer in tough conditions, which is great for hard tasks.

Real-life examples show how these differences matter. For robots, Orbitless Drives are chosen for their small size and power. But for heavy machines, Planetary Drives are better because they can carry more weight. It’s all about what the job needs.

Advantages and Disadvantages of Each Drive Type

Comparing Orbitless and Planetary Drives means looking at the good and the bad. Orbitless Drives are simple, efficient, and compact. This makes them great for tight spaces. Their design is less complex, leading to lower energy loss and better performance.

But, these drives have downsides too. Planetary Drives tend to cost more and might be hard to find in some places. For jobs needing high precision, these issues can be problematic. Yet, Planetary Drives are known for their high torque density and durability. They perform well in tough situations.

Planetary Drives, though, can be tricky to maintain. Their complex design can mean more maintenance and downtime. Choosing the right drive depends on the project’s specific needs and the setting. Engineers must think about these points to pick the best system for their goals.