The field of robotics is growing fast, spreading into many areas. Advanced gear technology is crucial for this growth. It helps achieve precision and efficiency in robots.

Advanced gear systems are key in many places, like factories, hospitals, or homes. This article looks at how these gears improve robots. We’ll see their importance in controlling motion, being precise, and efficient.

Understanding Advanced Gear Technology

Advanced gear technology is crucial to get. It’s about the design and use of mechanical gears. These gears change rotational motion into linear force. This change helps machines control speed and torque better. There are many types of gears like spur, helical, bevel, and worm gears. They are key for machinery and robotics to work right.

What is Gear Technology?

Gear technology definition is based on how these systems work well. Gears have main jobs like:

- Transmitting motion between machine parts

- Controlling the direction of motion

- Adjusting speed and force

Knowing the different types of gears helps us understand their use. Gears vary in shape and how they work. Each type meets certain needs in machines and robots.

The Evolution of Gear Systems in Robotics

History of gear systems is quite interesting, especially in robotics. Early robots used simple gear systems. This was just the start. Later, tools like computer-aided design (CAD) and lightweight materials made gears better. This improved how robots work.

Here’s a quick look at important moments in gear tech for robotics:

| Year | Development | Impact on Robotics |

|---|---|---|

| 1956 | Launch of Unimate, the first industrial robot | Highlighted the need for better gear systems |

| 1980s | Use of CAD in engineering | Made gear design more precise and prototyping faster |

| 2000s | Use of lightweight materials in making gears | Made robots more durable and efficient |

These gear technology improvements made robot systems more advanced. They are more reliable and work better now. It’s essential to know these changes to understand gear tech’s role in modern robotics.

The Role of Advanced Gear Technology in Robotics

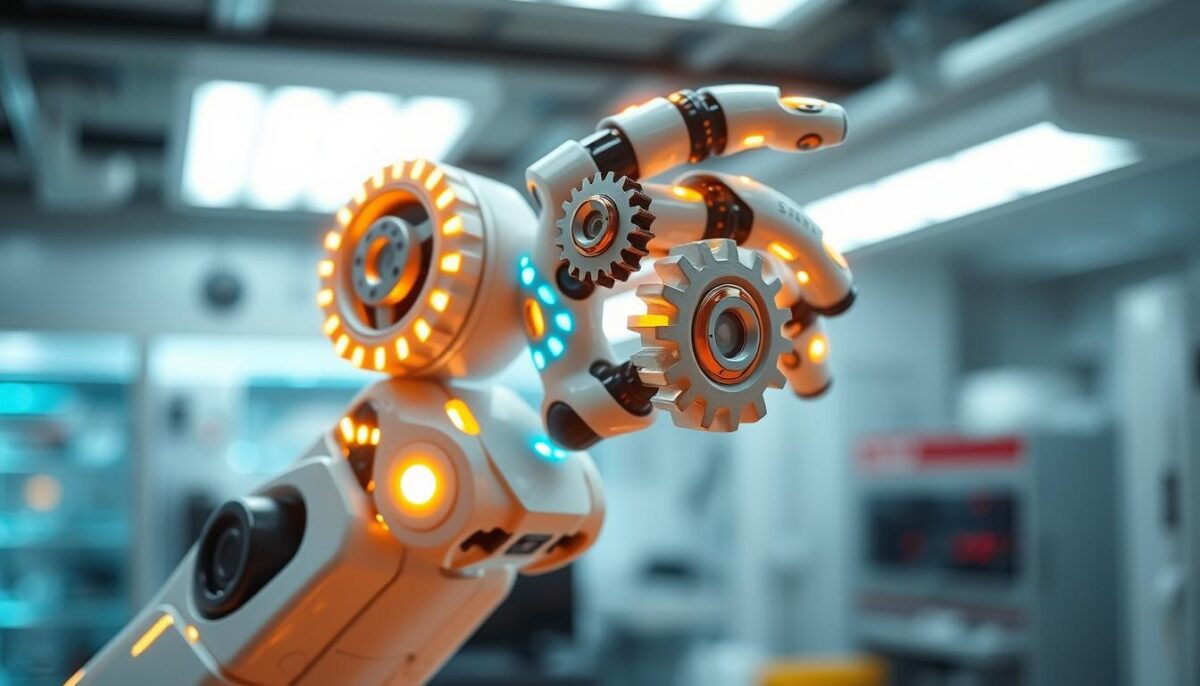

Advanced gear technology is key in making robots more precise and efficient. Innovative designs and materials help robots achieve great accuracy. This section looks at how gears help robot precision and better performance.

Enhancing Precision in Robotic Movement

For robots, being precise is essential, especially in making things or in surgery. Gears play a big part in how accurately robots move. They handle heavy loads well and respond quickly.

For example, servo motors and high-precision gears make robot arms work smoothly on assembly lines. This shows how important perfect motion control is. The right gears can greatly improve how robots do tasks that need a lot of precision.

Improving Efficiency and Performance

Advanced gears also make robots work better and use less energy. They use cutting-edge designs and materials to cut down on friction and weight. This means gears can save more energy and last longer.

This is especially true in car making and logistics. These areas have seen big cost savings and faster work because of better gears. It shows how modern gear systems can boost operational efficiency.

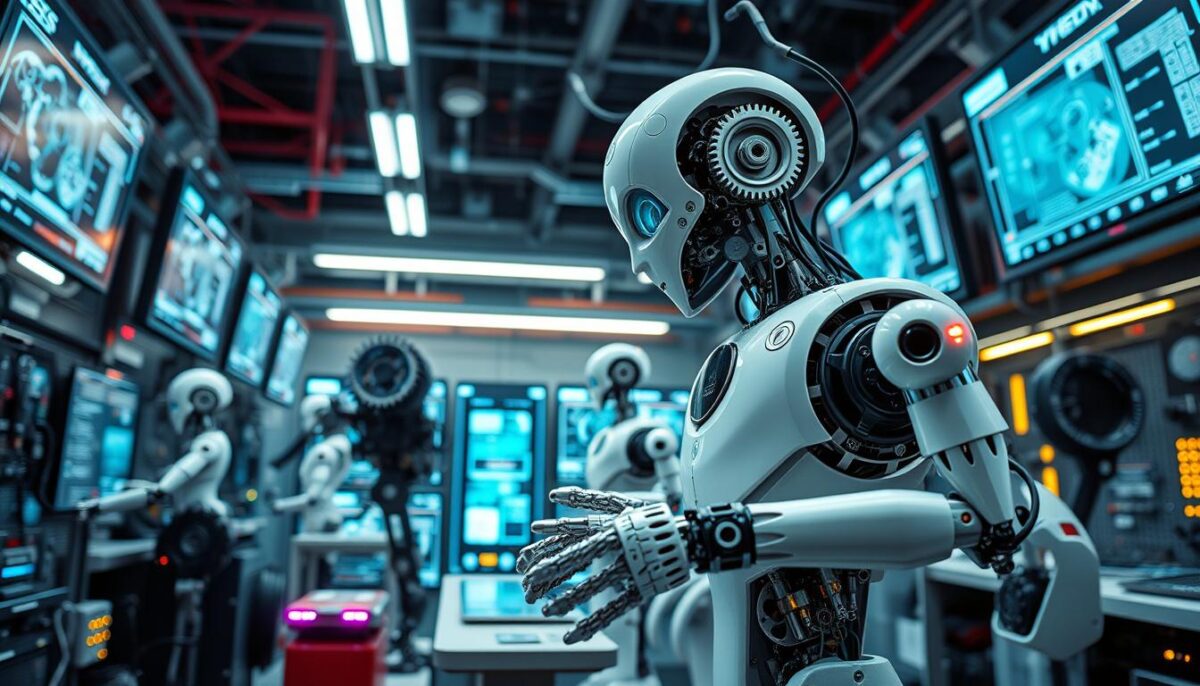

Applications of Advanced Gear Technology in Robotics

Advanced gear technology is crucial in various fields. It improves robots’ abilities and performance. This section looks into its use in industrial and medical robotics, plus consumer robotics and automation.

Industrial Robotics

Robots in industrial settings make production smoother. They depend on advanced gear designs. These machines are key for assembly, welding, and handling materials. They offer several benefits:

- Increased productivity through improved efficiency.

- Enhanced precision leading to reduced error rates.

- Lower operational costs due to minimized manual labor.

Electronics and automotive industries use advanced gear technology. This optimizes their work and helps them keep up with market changes. Thanks to high-speed operations, industrial robots change how we manufacture products.

Medical Robotics

In medical robotics, advanced gears are vital, especially in surgical robots. The da Vinci Surgical System is one example. It uses complex gears in healthcare for precise, minimally invasive surgeries. The benefits of these gears include:

- Providing surgeons with enhanced maneuverability and control.

- Reducing recovery time for patients due to smaller incisions.

- Improving overall surgical outcomes and patient safety.

Efforts are ongoing to develop even better gear systems. These improvements aim to streamline operations in various medical fields.

Consumer Robotics and Automation

Gear technology greatly enhances consumer robotics and home automation. It powers everything from cleaning robots to personal assistants. The advancements in gears help by:

- Smooth and efficient operation for everyday tasks.

- Enhanced user experience through responsive smart robots.

- Integration into smart homes to simplify daily routines.

With more people using automation, advanced gear technology becomes more important. It not only adds convenience but also improves our quality of life.

| Application Area | Benefits | Example Devices |

|---|---|---|

| Industrial Robotics | Increased productivity, enhanced precision | Automated assembly lines, welding robots |

| Medical Robotics | Improved accuracy, reduced recovery time | da Vinci Surgical System, robotic-assisted surgeries |

| Consumer Robotics | Smooth operation, enhanced user experience | Roomba, smart home assistants |

Future Trends in Gear Technology for Robotics

The future of gear technology looks bright, with big changes on the horizon. Smart gears are leading the way. They use IoT to boost performance as needed. This makes robots smarter, letting them adjust better to their surroundings.

Another big trend is using sustainable, lightweight materials for gears. 3D printing lets us create complex designs while cutting down on waste. This is good for the planet and makes gears better suited for robots today.

These advances will greatly improve robotics. More agile and eco-friendly robots are coming. As companies focus on doing better and being greener, gear technology will play a huge role in robotics’ future.